- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

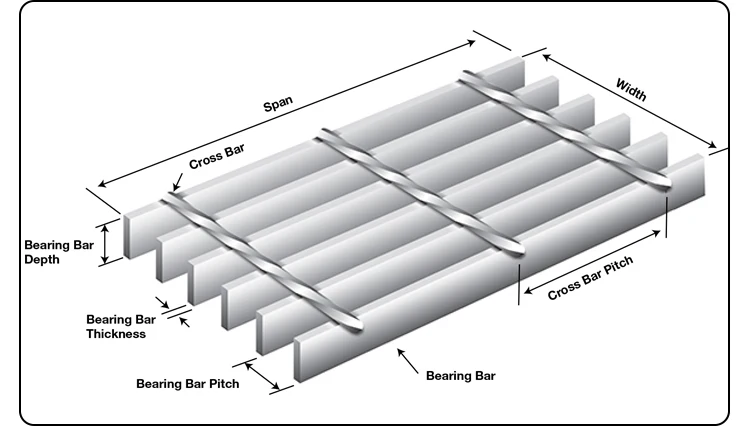

Professional-grade steel bar grating engineered for demanding industrial environments. Our galvanized steel grating combines exceptional load-bearing capacity with superior drainage, ventilation, and anti-slip safety. With hot-dip galvanized finish and customizable specifications, these steel walkway grating solutions deliver long-lasting performance across petrochemical, power generation, wastewater treatment, and commercial construction applications.

| Product Name | Galvanized steel grating |

| Product Keyword | steel grating/Stainless steel grille |

| Raw Material | Q235, galvanized, hot-dip galvanized, electrogalvanized, painted |

| Dimensions | Universal dimensions/As your demands |

| Surface | Hot dip galvanizing/coating or no treatment |

| Color | Silvery/as your request |

| Weight | As your requirement |

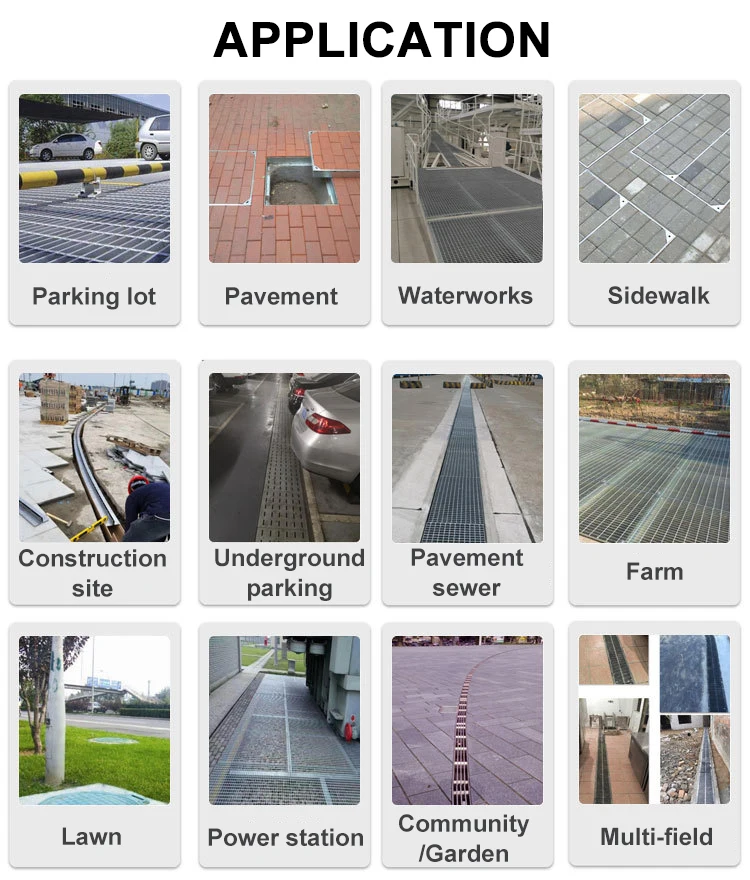

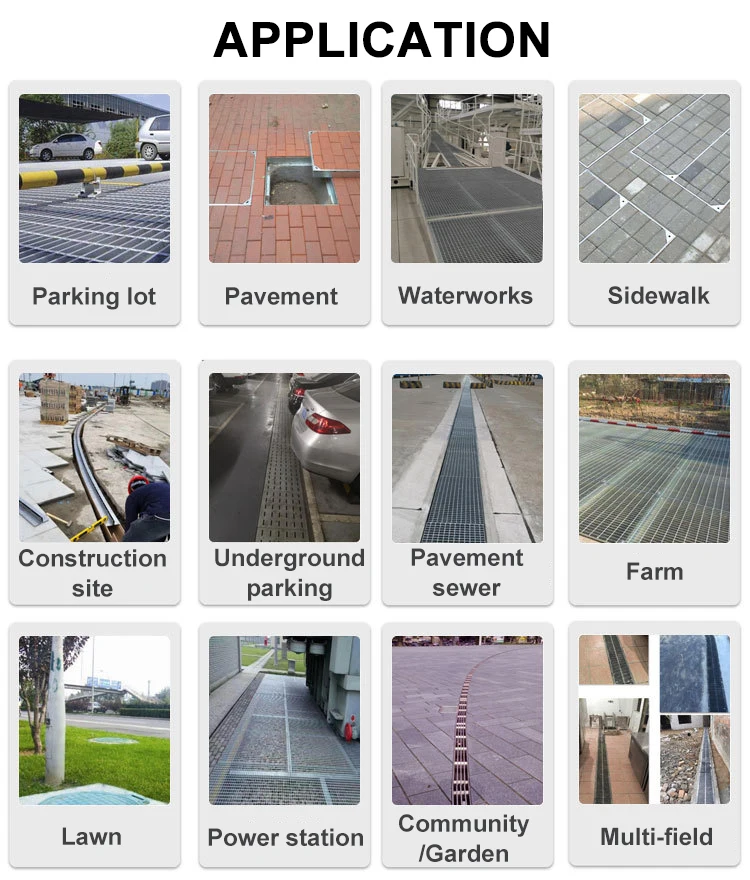

| Application(Gratings) | Widely used in drainage ditches for food factories, hotels, kitchens, schools, canteens, vegetable processing plants, car washes, swimming pools, hospitals, pharmaceutical factories, and other drainage facilities such as garden facilities |

| Application(steel Gratings) | Applied in civil and commercial buildings, subway and other municipal engineering fields, the product has many characteristicssuch as lightweight, high strength, anti-corrosion, maintenance free, and aesthetics. It can be used for suspended ceilings, indoor and outdoor decoration, platform walkways, ventilation windows (wells), etc. |

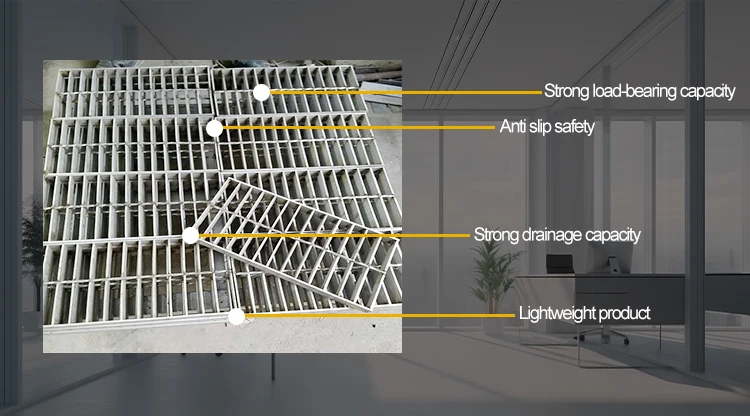

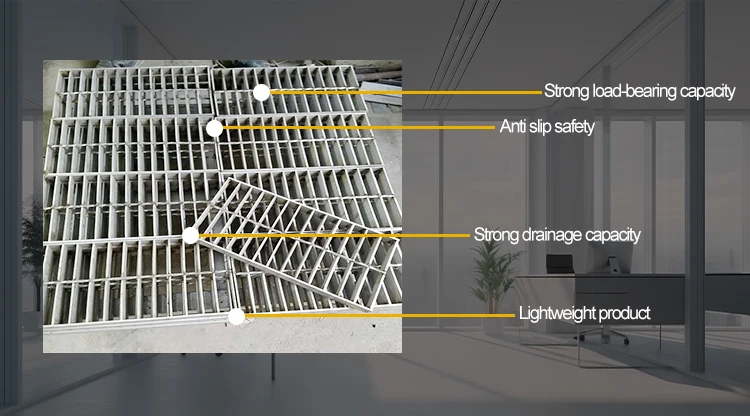

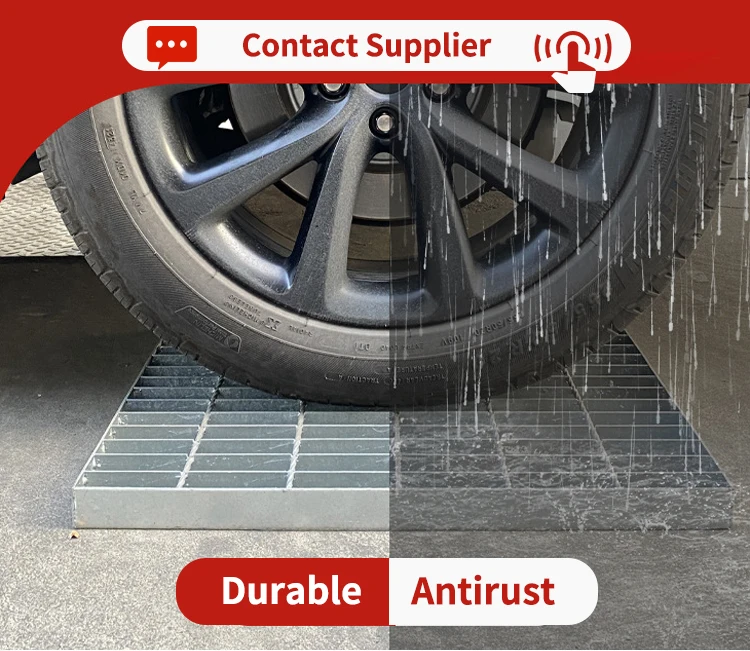

| Feature | Strong load-bearing, anti slip safety, large drainage capacity, anti-corrosion and rust prevention. |

| Package | wooden pallets or steel pallets, or as your request |

| Note | OEM service is available |

Applications: Airport runways, marine terminals, highway bridge decking, forklift traffic zones

Engineering Focus: Utilizes thicker bearing bars (6mm-10mm) to withstand concentrated rolling loads

Load Capacity: Supports up to 1000+ lbs/sq ft with minimal deflection

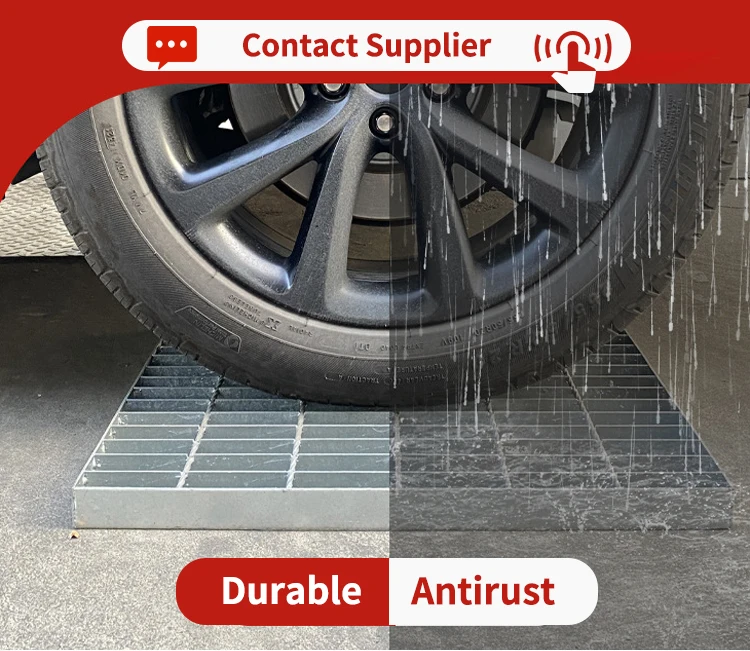

Durability: Hot-dip galvanized finish ensures 50+ year service life in outdoor environments

Applications: Oil & gas platforms, chemical plants, wet/icy environments, industrial stairs

Safety Features: Diamond-pattern serrations increase slip coefficient by 40% compared to plain surface

Compliance: Meets OSHA walking surface requirements for industrial facilities

Material Options: Available in carbon steel or 316 stainless steel for corrosive environments

Applications: Commercial walkways, ADA-compliant ramps, architectural facades, public facilities

Design Standards: 11mm bearing bar spacing prevents high-heel entrapment per ADA guidelines

Aesthetic Appeal: Press-locked construction provides clean, uniform appearance

Load Rating: Designed for 100 lbs/sq ft live load with appropriate deflection limits

Applications: Mezzanine platforms, equipment access flooring, drainage covers, ventilation panels

Structural Integration: Custom sizing and edge preparation for seamless installation

Multi-Performance: Combines load-bearing, drainage, and ventilation in single solution

Fire Safety: Open design allows sprinkler system penetration and smoke evacuation

Drawing-Based Manufacturing: CNC cutting and welding from customer CAD specifications

Edge Preparation: Professional beveling, framing, and fastening hole preparation

Size Flexibility: Custom panels from 1'×1' to 4'×20' or larger assemblies

Engineering Support: Load calculation tables and structural drawings provided

Material Traceability: Mill test certificates (MTC) provided for all raw materials

Welding Inspection: 100% visual inspection with periodic destructive testing

Galvanizing Quality: Coating thickness testing per ASTM A123 (minimum 85 microns)

Load Testing: Sample panels tested to 3× design load for safety verification

Production Capacity: 5000+ tons monthly output with expedited delivery options

Packaging Excellence: Steel pallet bundling with protective wrapping for international shipping

Technical Documentation: Complete material certifications and installation guidelines included

Superior Strength-to-Weight Ratio: Open mesh design reduces dead load by 30-50% compared to solid steel plate while maintaining structural capacity.

Maximum Drainage Efficiency: 85%+ open area allows immediate water evacuation, eliminating standing water and ice formation risks.

Enhanced Safety Performance: Serrated surface options provide slip coefficient of 0.7+ (wet conditions), exceeding OSHA requirements.

Long-Term Durability: Hot-dip galvanization creates metallurgical bond that self-heals minor scratches, ensuring decades of maintenance-free service.

Versatile Installation: Compatible with standard structural steel framing, concrete embedment, or specialized support systems.

Petrochemical & Refining: Platform grating, equipment access, pipe rack flooring

Water Treatment: Clarifier walkways, pump station flooring, screening equipment covers

Power Generation: Turbine platforms, cooling tower access, substation flooring

Marine & Offshore: Dock decking, vessel gangways, offshore platform systems

Commercial Construction: Mezzanine flooring, parking structures, architectural features

Food Processing: Sanitary drainage systems, equipment platforms, processing area flooring

Carbon Steel Q235: Cost-effective solution for standard industrial applications

Stainless Steel 304: Moderate corrosion resistance for food/pharmaceutical environments

Stainless Steel 316: Superior corrosion resistance for marine/chemical applications

Hot-Dip Galvanized (HDG): Premium corrosion protection (ASTM A123 compliant)

Electro-Galvanized: Light-duty corrosion protection for indoor applications

Powder Coated: Custom color options with enhanced UV resistance

Mill Finish: Uncoated for immediate painting or specialized coating application

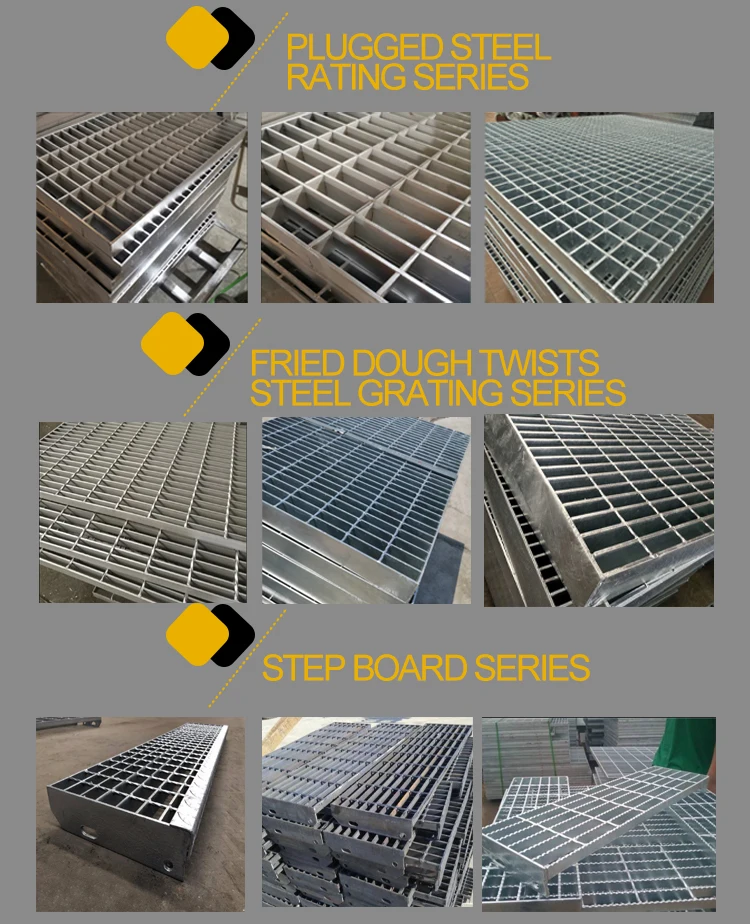

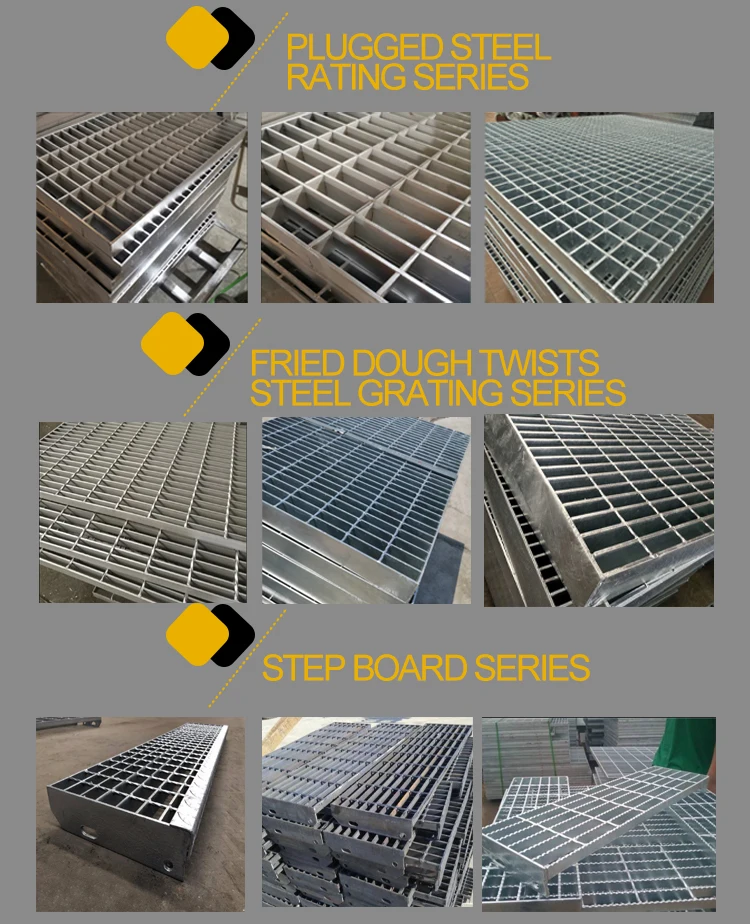

Welded Grating: Maximum strength and rigidity for heavy-load applications

Press-Locked Grating: Clean appearance with good load capacity for architectural use

Riveted Grating: Traditional construction method for replacement/restoration projects

Engineering Resources:

Load capacity calculation tables for all standard configurations

CAD/DWG files available for design integration

BIM models for Revit and other 3D design platforms

Installation guidelines and fastening specifications

Quality Certifications:

ISO 9001:2015 manufacturing quality management

Material test certificates for all raw materials

Third-party load testing reports available

Galvanizing certification per ASTM A123

Ready to specify the perfect steel grating solution for your project?

Upload Your Drawings - Get Custom Quote in 24 HoursOur engineering team provides precise pricing based on your exact specifications, load requirements, and installation conditions.

Download Complete Specification GuideAccess our comprehensive PDF catalog with load tables, dimension charts, and installation guidelines.

Speak with Application SpecialistGet expert guidance on material selection, load calculations, and cost optimization for your specific project requirements.

Quality Guaranteed | Global Shipping | Technical Support Included

Professional-grade steel bar grating engineered for demanding industrial environments. Our galvanized steel grating combines exceptional load-bearing capacity with superior drainage, ventilation, and anti-slip safety. With hot-dip galvanized finish and customizable specifications, these steel walkway grating solutions deliver long-lasting performance across petrochemical, power generation, wastewater treatment, and commercial construction applications.

| Product Name | Galvanized steel grating |

| Product Keyword | steel grating/Stainless steel grille |

| Raw Material | Q235, galvanized, hot-dip galvanized, electrogalvanized, painted |

| Dimensions | Universal dimensions/As your demands |

| Surface | Hot dip galvanizing/coating or no treatment |

| Color | Silvery/as your request |

| Weight | As your requirement |

| Application(Gratings) | Widely used in drainage ditches for food factories, hotels, kitchens, schools, canteens, vegetable processing plants, car washes, swimming pools, hospitals, pharmaceutical factories, and other drainage facilities such as garden facilities |

| Application(steel Gratings) | Applied in civil and commercial buildings, subway and other municipal engineering fields, the product has many characteristicssuch as lightweight, high strength, anti-corrosion, maintenance free, and aesthetics. It can be used for suspended ceilings, indoor and outdoor decoration, platform walkways, ventilation windows (wells), etc. |

| Feature | Strong load-bearing, anti slip safety, large drainage capacity, anti-corrosion and rust prevention. |

| Package | wooden pallets or steel pallets, or as your request |

| Note | OEM service is available |

Applications: Airport runways, marine terminals, highway bridge decking, forklift traffic zones

Engineering Focus: Utilizes thicker bearing bars (6mm-10mm) to withstand concentrated rolling loads

Load Capacity: Supports up to 1000+ lbs/sq ft with minimal deflection

Durability: Hot-dip galvanized finish ensures 50+ year service life in outdoor environments

Applications: Oil & gas platforms, chemical plants, wet/icy environments, industrial stairs

Safety Features: Diamond-pattern serrations increase slip coefficient by 40% compared to plain surface

Compliance: Meets OSHA walking surface requirements for industrial facilities

Material Options: Available in carbon steel or 316 stainless steel for corrosive environments

Applications: Commercial walkways, ADA-compliant ramps, architectural facades, public facilities

Design Standards: 11mm bearing bar spacing prevents high-heel entrapment per ADA guidelines

Aesthetic Appeal: Press-locked construction provides clean, uniform appearance

Load Rating: Designed for 100 lbs/sq ft live load with appropriate deflection limits

Applications: Mezzanine platforms, equipment access flooring, drainage covers, ventilation panels

Structural Integration: Custom sizing and edge preparation for seamless installation

Multi-Performance: Combines load-bearing, drainage, and ventilation in single solution

Fire Safety: Open design allows sprinkler system penetration and smoke evacuation

Drawing-Based Manufacturing: CNC cutting and welding from customer CAD specifications

Edge Preparation: Professional beveling, framing, and fastening hole preparation

Size Flexibility: Custom panels from 1'×1' to 4'×20' or larger assemblies

Engineering Support: Load calculation tables and structural drawings provided

Material Traceability: Mill test certificates (MTC) provided for all raw materials

Welding Inspection: 100% visual inspection with periodic destructive testing

Galvanizing Quality: Coating thickness testing per ASTM A123 (minimum 85 microns)

Load Testing: Sample panels tested to 3× design load for safety verification

Production Capacity: 5000+ tons monthly output with expedited delivery options

Packaging Excellence: Steel pallet bundling with protective wrapping for international shipping

Technical Documentation: Complete material certifications and installation guidelines included

Superior Strength-to-Weight Ratio: Open mesh design reduces dead load by 30-50% compared to solid steel plate while maintaining structural capacity.

Maximum Drainage Efficiency: 85%+ open area allows immediate water evacuation, eliminating standing water and ice formation risks.

Enhanced Safety Performance: Serrated surface options provide slip coefficient of 0.7+ (wet conditions), exceeding OSHA requirements.

Long-Term Durability: Hot-dip galvanization creates metallurgical bond that self-heals minor scratches, ensuring decades of maintenance-free service.

Versatile Installation: Compatible with standard structural steel framing, concrete embedment, or specialized support systems.

Petrochemical & Refining: Platform grating, equipment access, pipe rack flooring

Water Treatment: Clarifier walkways, pump station flooring, screening equipment covers

Power Generation: Turbine platforms, cooling tower access, substation flooring

Marine & Offshore: Dock decking, vessel gangways, offshore platform systems

Commercial Construction: Mezzanine flooring, parking structures, architectural features

Food Processing: Sanitary drainage systems, equipment platforms, processing area flooring

Carbon Steel Q235: Cost-effective solution for standard industrial applications

Stainless Steel 304: Moderate corrosion resistance for food/pharmaceutical environments

Stainless Steel 316: Superior corrosion resistance for marine/chemical applications

Hot-Dip Galvanized (HDG): Premium corrosion protection (ASTM A123 compliant)

Electro-Galvanized: Light-duty corrosion protection for indoor applications

Powder Coated: Custom color options with enhanced UV resistance

Mill Finish: Uncoated for immediate painting or specialized coating application

Welded Grating: Maximum strength and rigidity for heavy-load applications

Press-Locked Grating: Clean appearance with good load capacity for architectural use

Riveted Grating: Traditional construction method for replacement/restoration projects

Engineering Resources:

Load capacity calculation tables for all standard configurations

CAD/DWG files available for design integration

BIM models for Revit and other 3D design platforms

Installation guidelines and fastening specifications

Quality Certifications:

ISO 9001:2015 manufacturing quality management

Material test certificates for all raw materials

Third-party load testing reports available

Galvanizing certification per ASTM A123

Ready to specify the perfect steel grating solution for your project?

Upload Your Drawings - Get Custom Quote in 24 HoursOur engineering team provides precise pricing based on your exact specifications, load requirements, and installation conditions.

Download Complete Specification GuideAccess our comprehensive PDF catalog with load tables, dimension charts, and installation guidelines.

Speak with Application SpecialistGet expert guidance on material selection, load calculations, and cost optimization for your specific project requirements.

Quality Guaranteed | Global Shipping | Technical Support Included